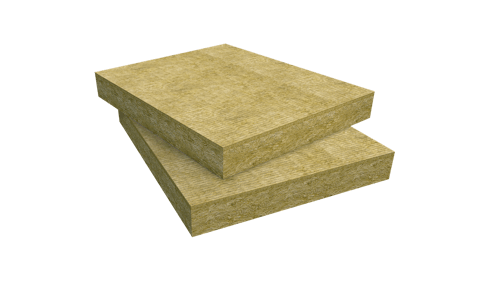

Toprock® DD is a high-density uncoated stone wool insulation board for low-slope roof applications

Toprock® DD is a suitable substrate board for all low-slope roof decks and is compatible as the substrate for mechanically attached membrane systems.

It has excellent acoustic properties. The product can be used as either a base layer of thermal insulation in an acoustic assembly with Toprock® DD Plus or as the top layer of a hybrid roof assembly with polyisocyanurate or other roof insulations.

Read our Low slope roofing brochure

Properties:

- Non-combustible, meeting FM 4470 NCC (Non-Combustible Core) Rating

- Will not warp or cup

- Dimensionally stable—provides a long-term, consistent thermal performance

- High impact resistance

- Excellent acoustic reduction, absorption and impact (rain noise) performance

- Made from natural & recycled materials

- ROCKWOOL® can contribute to earning LEED® points