ROCKWOOL products – including roof insulation boards, slabs, rolls and granulate – are specially designed to cope with a variety of conditions. Our experts can be on hand to help facilitate the smooth and speedy installation with local fitters, while the materials used in the build are maintained to the highest safety standards.

Available in a selection of sizes and thicknesses, our innovative stone wool products are both durable and effective for the lifetime of your building.

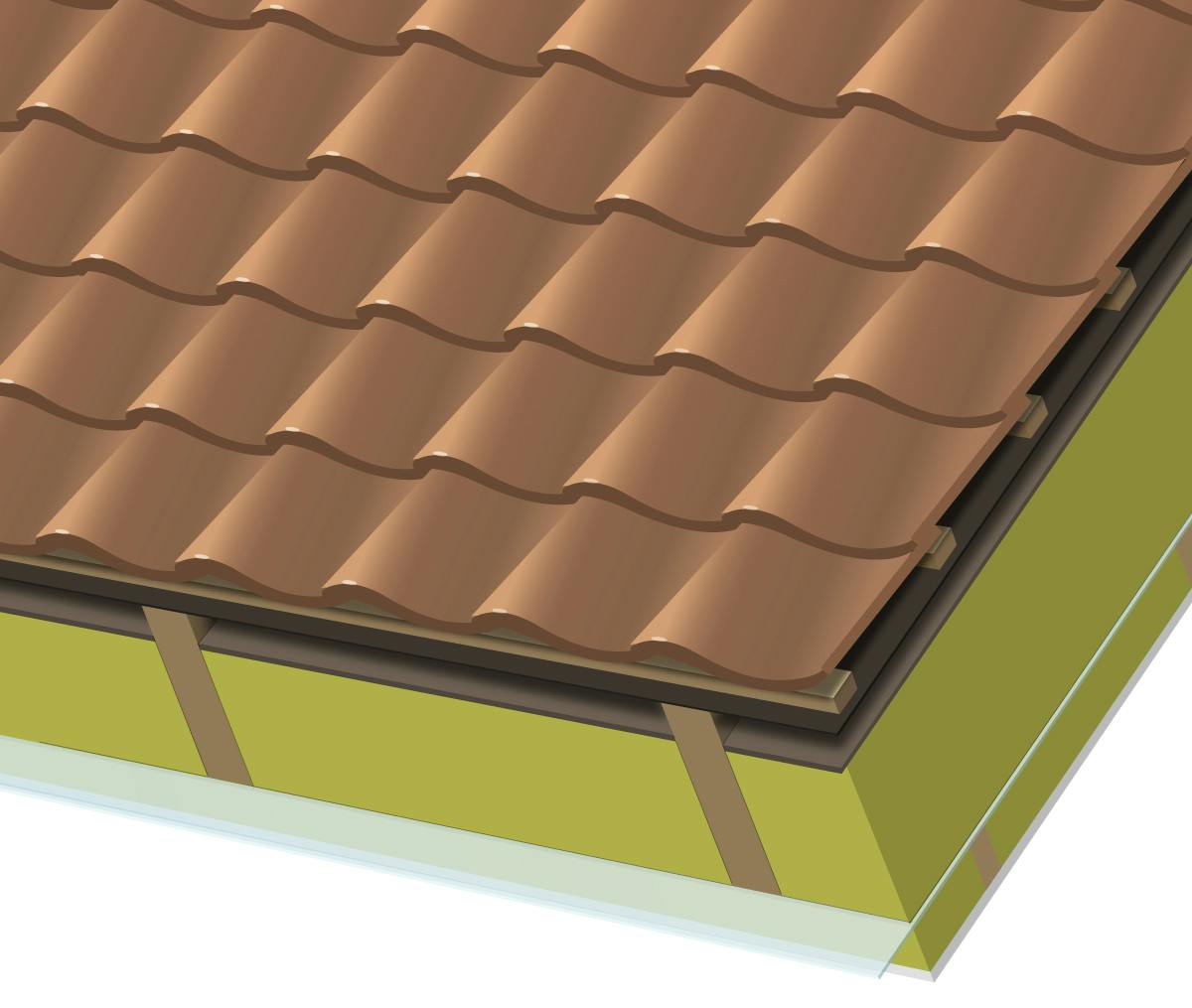

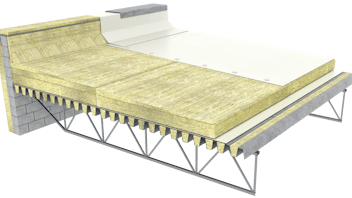

Our flat roof range maintains its high performance against cold and moisture, while the versatile installation methods of our pitched roof products means you can protect your project with above, in between and below rafter insulation or with easy-to-fit loft floor solutions, to achieve the best results.

Benefits of our stone wool insulation include4:

Thermal properties

Specially treated stone wool has optimal insulative properties. Warm air can be trapped inside the home and cold air can be kept out to maintain comfortable temperatures.

Noise-absorbing

The acoustic properties of stone wool can better contain sound within a building, providing better acoustics for budding rock stars, or keep it outside for high focussed office workers and eager students alike.

Sustainable

Stone wool is both a natural and plentiful source. By choosing to use fewer alternative materials we’re maintaining sustainable practice – vital in the construction industry.